Copper Foil for Beginners

Table of ContentsTop Guidelines Of Copper FoilCopper Foil - TruthsIndicators on Copper Foil You Need To KnowAn Unbiased View of Copper FoilThe smart Trick of Copper Foil That Nobody is DiscussingFacts About Copper Foil Uncovered

Number 1 was constructed with PWB products as well as one can see the BGAs in the top left and best corners. Wiring demand, there are likewise electrical efficiency considerations that are a lot more vital to the high performance part of the market. Wire bond connections can restrict electric efficiency for 2 reasons: added inductance in the wire loophole, which generates signal delay and restricted availability of I/O for voltage and also ground because they are sharing the offered cable bond pitch with signals.Figure 4 reveals the I/O vs. chip size for microvia item at the above kept in mind function sizes as a comparison fully location selection capability of an MLC substrate with the same 250 micron pitch as used in Fig. 3. For 2 mm chips, one microvia layer supplies 100% of the I/O.

In the copper foil method, edges of glass are wrapped in slim copper aluminum foil around. The aluminum foil covers the whole side of the glass as well as concerning one-sixteenth of the front and back sides.

Copper Foil - An Overview

When used as component of the design, leading might be wider. Aluminum foil is used evenly to old glass with the very same width of foil to the front side as the back.

Copper foil is still utilized in contemporary leaded glass, it is so labor intensive that high quality brand-new job is typically the very same cost as vintage work. An instance of loosened foil and 2 items of glass wrapped in copper foil. Pieces are signed up with by applying solder to the copper wrapping.

After the whole color is constructed, added solder is related to all joints to develop up the leading to a constant width as well as elevation. The copper aluminum foil is covered around the whole side. This is a profile of two pieces of glass wrapped in copper foil before soldering. Copper foil creates slim joints.

Copper Foil Things To Know Before You Buy

By Kate Riley September 26, 2016 Copper accents have been trending for a few years, as well as are equally as popular this loss as they have actually been in current years. I understood to play around with some copper aluminum foil tape I discovered online, it's actually securing sticky but I thought it would certainly be fun to craft with it so I ordered a roll from Amazon.com (also a roll of a little thicker gold metal adhesive tape) and also got creative with both of them.

Copper is a soft, malleable steel which has actually been used in an extremely variety of methods throughout history. Copper aluminum foil, specifically, is frequently used for the building and construction of stained glass as well as is a requirement for most tarnished glass tasks. Enjoy your fingers, the edges are VERY sharp! Copper foil is a slice of copper that is quickly formed in innovative ways and is made use of to hold the glass items in position for stained glass tasks.

The Basic Principles Of Copper Foil

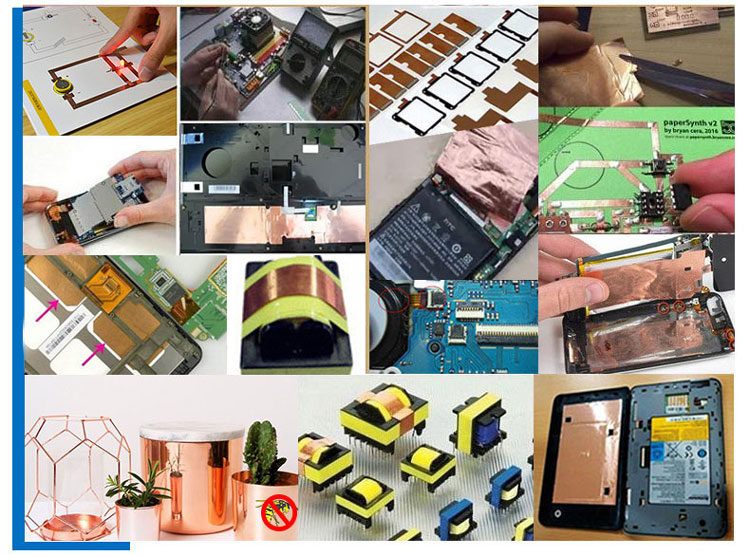

Simply be sure you don't utilize way too much copper aluminum foil as it can make the piece heavy, troublesome and more likely to break when relocated. Copper aluminum foil is extensively used in expert and also do it yourself click this stained glass jobs, tarnished glass repair, digital sectors, as well as is utilized for it transcends conductivity in some auto parts.

Put the lid on tight as well as it will expand the life of the copper. Any kind of type of airtight container will certainly work, the concept is to lower the exposure to warm as well as the components (consisting of AIR). On top of that, be certain to save the container or the bag in an amazing, dark and also completely dry area.

Copper aluminum foil is the base copper density used on external and also internal layers. The Copper Aluminum foil can be pre-attached by the laminate producer to a base material core or it can be introduced in a multi layer board as copper foil prior to pushing. On internal layers the last copper density remains that of the base copper aluminum foil. copper foil.

Copper Foil for Dummies

For 1 layer and also IMS boards there is no galvanic plating process.

Copper foil is a reasonably unusual anonymous product amongst the several different home products that are dealt yearly. Nonetheless, uses of the aluminum foil continue to be numerous as well as it has numerous applications throughout the house and in market. It isn't utilized in the majority of homes due to the fact that it was mainly replaced by light weight aluminum foil due to its much better adaptability and also warmth resistance.

The very first application that copper foil succeeds in is in producing tarnished glass art. Tarnished glass art is the process of cutting tarnished or colored glass and after that signing up with the pieces with each other to create gorgeous styles. Copper foil plays a huge role in this procedure because it is utilized to join the glass items with each other.

Copper Foil Fundamentals Explained

Hereafter, the foil is cut right into strips and also is placed between both items of glass. The glass edges are then covered with copper tape that is adhesive and after that they are soldered together to bond both pieces of glass together. This produces a strong bond in between the glass items which will her explanation certainly last for many years.

Since Copper Foil is so wonderful at holding little bits of glass with each other, it is often made use of when windows are harmed or damaged. The window items are generally separated while a little the aluminum foil strip is placed in the middle of both littles glass. Hereafter, the strips are covered with each other to shape the home windows with each other.